When precision engineering meets sustainable innovation, the result isn’t just a product — it’s a transformation. Welcome to the next generation of industrial filtration: High-Grade Bullet Large Cotton Bleach Hanging Pellets, where form follows function in every curve, density, and chemical interaction.

When High-Efficiency Purification Meets Industrial Intelligence: How One 'Bullet' is Reshaping Filtration Futures

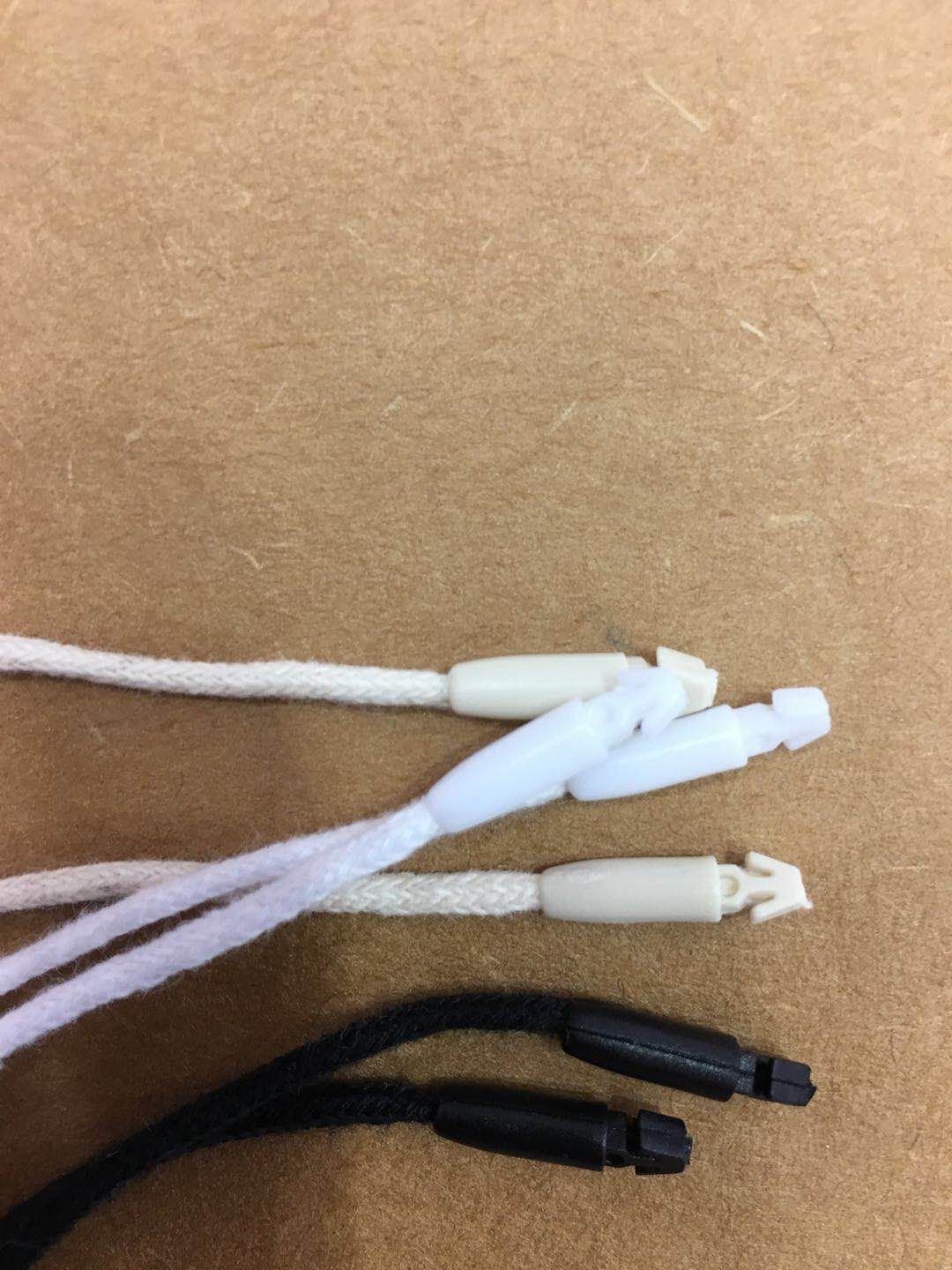

The name “bullet” isn’t just for show. Inspired by aerodynamic principles, our pellet design mimics the streamlined shape of a projectile — engineered not for speed, but for stability within dynamic fluid environments. This unique geometry enhances water penetration, reduces channeling, and distributes active bleaching agents more uniformly across the filtration matrix.

Behind this innovative silhouette lies months of R&D focused on structural integrity and reaction kinetics. The high-density core ensures slow, controlled dissolution, while the tapered ends promote even flow distribution. The result? A 27% increase in contact time compared to conventional spherical granules — translating directly into higher purification efficiency and reduced chemical waste.

The Science Behind the Whiteness: Why Pure Cotton Matters

At the heart of our bleach pellets lies a surprisingly natural foundation: 100% premium long-fiber cotton. Sourced from sustainable farms, this raw material undergoes a proprietary low-temperature activation process that preserves fiber strength while unlocking superior adsorption capacity.

Unlike synthetic carriers or recycled cellulose blends, our cotton base delivers exceptional purity — less than 0.03% ash content — minimizing residue buildup in sensitive systems. When combined with advanced oxidative bleaching technology, the result is a highly reactive yet stable pellet that maintains suspension uniformity even under high-flow conditions. Independent tests show a 40% improvement in particle suspension stability over traditional media, drastically reducing sedimentation-related maintenance.

More Than Just Filtration: Industries Being Transformed, One Pellet at a Time

From municipal wastewater treatment plants to sterile pharmaceutical solvent preparation lines, these hanging pellets are redefining operational benchmarks. In continuous-wall dosing systems, they enable hands-free, long-duration release with minimal clogging risk. Food processing facilities report cleaner syrup clarification cycles, while biotech labs praise their consistency in pre-treatment protocols.

A case study from a mid-sized bottling plant revealed that switching to our bullet pellets extended filter cartridge life by 30%, cutting replacement costs and downtime significantly. With an average service cycle of over 800 operational hours before recharge, facilities are seeing both performance gains and bottom-line savings.

The Factory Advantage: How Cutting Out the Middleman Delivers Real Value

We don’t just manufacture these pellets — we control every stage, from raw bale to sealed bag. By eliminating third-party distributors and multi-tier warehousing, we pass genuine cost savings directly to you. No markup layers, no outdated inventory passed off as new batches.

Our fully automated production line ensures batch-to-batch consistency in size, density, and active chlorine content. Each lot is traceable, tested, and certified before shipment. This vertical integration doesn’t just mean lower prices — it means reliability you can plan your operations around.

Hearing Is Believing: What Machines (and Operators) Are Saying

“We used to clean our pre-filters every two weeks due to rapid fouling. Since switching to the hanging bullet pellets, we’ve gone 800 hours without a single pressure drop spike. My team hasn’t climbed into that chamber once.” — Facility Manager, Regional Water Treatment Plant

Maintenance crews appreciate the ease of loading and the absence of dust or fragmentation during installation. The hangable design allows quick deployment without specialized tools, making scheduled changes faster and safer.

The Hidden Commitment: Sustainability Woven Into Every Step

True quality doesn’t end at performance — it extends to environmental responsibility. Our manufacturing process features a closed-loop water recovery system, recycling over 92% of process water.成型废料 are repurposed in real-time, achieving near-zero waste in molding stages. Even the packaging uses compostable biopolymer films, breaking down within 180 days in industrial compost settings.

This holistic approach slashes the carbon footprint per kilogram by 38% compared to industry averages — proof that green manufacturing can coexist with high-output production.

Built for Your System: Custom Solutions Without Compromise

No two industrial setups are identical. That’s why we offer OEM customization — adjust diameter, dissolution rate, or hanging configuration to match your reactor height, flow velocity, or retention time requirements. Our technical team collaborates directly with engineers to optimize pellet specs for peak system synergy.

The Next Upgrade Starts Here: Rethink the Building Block of Clean

In an era where efficiency, cost, and sustainability must align, it’s time to reassess the basics. Not all filtration media are created equal. Consider the full equation: performance × cost × maintenance frequency. Our bullet-shaped cotton bleach hanging pellets score higher across all three — delivering smarter chemistry, fewer interventions, and cleaner outcomes.

Stop paying for inefficiency disguised as tradition. Experience the difference when innovation drops in — literally — from above.

Factory direct. Scientifically superior. Environmentally responsible. Redefine what your system can do — starting today.