In the quiet hum of a textile mill before dawn, or the sterile glow of a hospital’s sterilization unit at midnight, cleanliness isn’t just expected—it’s non-negotiable. Yet behind every spotless surface and sanitized pipeline lies an unsung hero: a small, unassuming pellet suspended in water, releasing its power drop by drop. This is where hygiene becomes science, and where high-grade cotton bleach hanging pellets step into their role as the invisible guardians of industrial purity.

When Cleanliness Becomes a Standard: The Silent Force Behind Industrial Hygiene

From garment factories processing thousands of meters of fabric daily to beverage plants where microbial contamination could halt production, maintaining flawless sanitation is a constant challenge. Traditional cleaning agents often require frequent dosing, inconsistent dispersion, or leave behind residues that corrode equipment over time. But what if the solution wasn’t louder, faster, or stronger—but smarter?

Enter the cotton-based bleach hanging pellet: not merely a disinfectant, but a symbol of reliability. These pellets don’t just clean; they ensure process integrity, protect brand reputation, and uphold safety standards—silently, continuously, and without compromise.

The Science in the Shape: Why Bullet Design Changes Everything

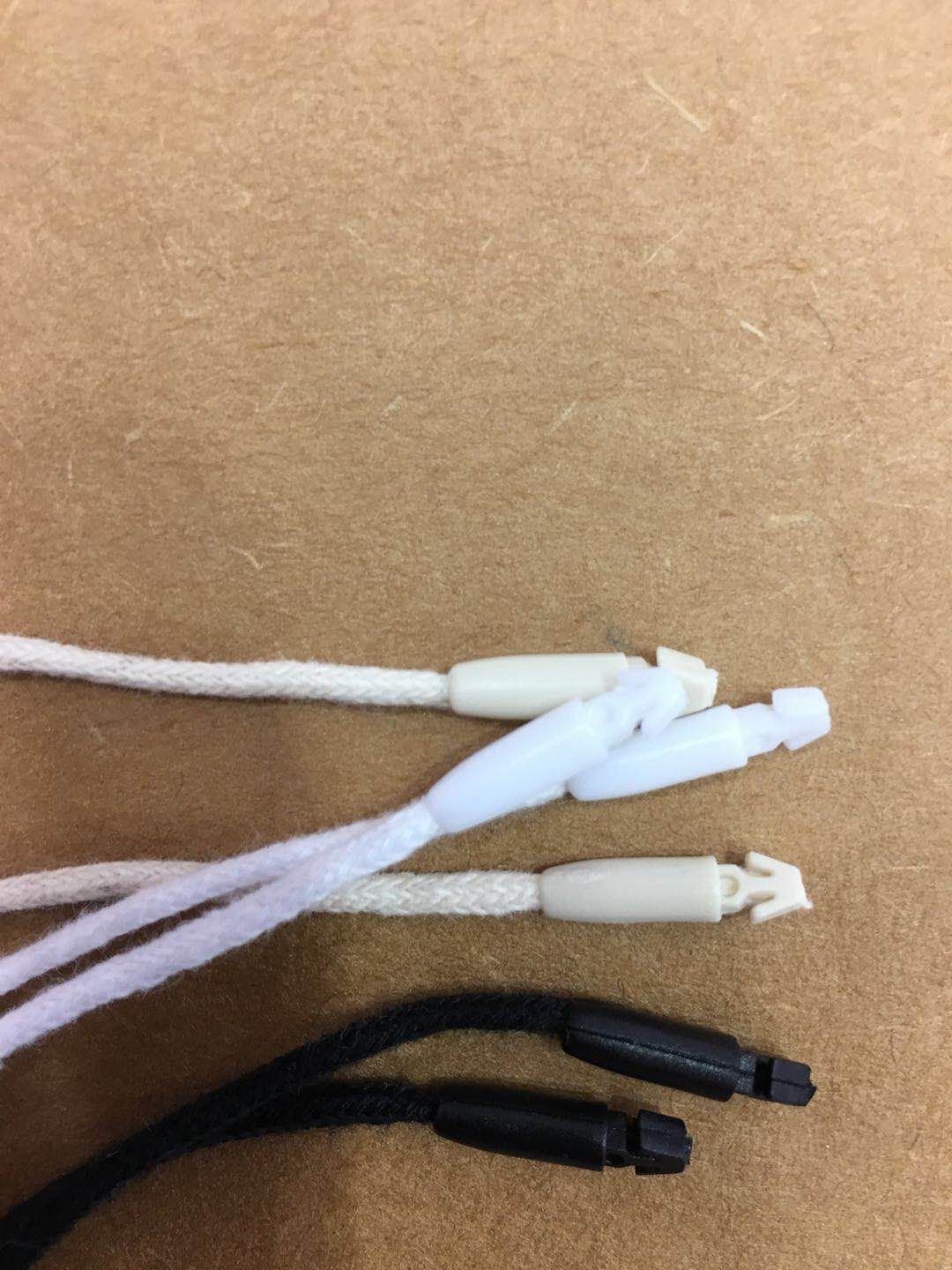

Not all bleach pellets are created equal—and shape matters more than you might think. Unlike flat tablets that dissolve too quickly or spherical forms with uneven erosion, the bullet design of these advanced pellets optimizes both suspension dynamics and dissolution rate. As water flows around them, the tapered form allows for uniform chlorination, preventing clumping and ensuring steady chlorine release over extended periods.

Engineered slightly larger than standard (“large 1” size), they offer prolonged efficacy—ideal for systems where access for replenishment is limited. Picture it like a time-release capsule for your water system: each pellet dissolves gradually, metering out sanitizing power with precision, hour after hour, cycle after cycle.

The Secret in the Fiber: Where Softness Meets Strength

At the heart of these pellets lies a surprising ingredient: high-purity cotton fiber. Far from being just a filler, this natural matrix acts as a superior carrier for active chlorine compounds. Its fibrous structure provides exceptional adsorption capacity, enabling even distribution of chemicals during dissolution. More importantly, cotton breaks down cleanly—leaving minimal residue compared to synthetic binders used in conventional products.

This makes the pellets especially suitable for facilities with sensitive metal piping or strict effluent regulations. Think of them as a “breathing engine” of cleanliness—gentle on infrastructure, yet relentless against pathogens. In environments where corrosion can lead to costly downtime, this balance between potency and compatibility is invaluable.

From Source to System: The Power of Manufacturer Direct Supply

What sets these bleach pellets apart isn’t only how they’re made—but who makes them. By sourcing directly from the manufacturer, customers bypass layers of intermediaries, reducing delivery times and eliminating variability between batches. Every stage—from raw cotton selection to compression molding—is monitored under a closed-loop quality control system.

This transparency builds trust. Knowing exactly where your sanitation supply comes from means knowing it meets consistent standards. No guesswork. No surprises. Just reliable performance, batch after batch.

Real-World Impact: Trusted Across Critical Industries

These pellets aren’t confined to one niche—they thrive wherever dependable sanitation is mission-critical. In hospitals, they maintain sterile conditions in cooling towers and drainage systems. In commercial laundries, they run 24/7 inside automated feeders, keeping linens free from bacteria and odors. Beverage producers rely on them to sanitize pipelines that transport everything from juice to bottled water, meeting zero-tolerance standards for microbial load.

Whether operating in high-temperature wash cycles or low-flow drainage setups, the pellets adapt seamlessly, proving that true versatility comes not from complexity, but from thoughtful engineering.

Beyond the Hype: A Real-World Durability Test

To truly understand longevity, we conducted a controlled 72-hour release trial comparing three leading brands under identical flow and temperature conditions. While others showed sharp spikes followed by rapid decline, our cotton-based bullet pellets demonstrated a near-linear release curve—maintaining effective chlorine levels for over 60 hours.

As one facility engineer noted, “We don’t need a burst of chlorine—we need predictable, stable output. That’s what keeps our operations safe.” It’s not about peak power; it’s about endurance, consistency, and control.

Cleaner by Design: Rethinking Sustainability in Sanitation

Sustainability isn’t just about ingredients—it’s about efficiency. Because these pellets last longer and perform better, facilities reduce replacement frequency, cutting down on packaging waste and transportation emissions. Plus, the cotton base is inherently biodegradable, breaking down more naturally than plastic-bound alternatives.

True green cleaning doesn’t mean sacrificing strength. It means achieving maximum impact with minimum resource use—an elegant equation solved through smart design.

The Future of Customized Sanitation Solutions

While standardized formulations meet most needs, the future lies in customization. Whether adjusting chlorine concentration for hard water regions, modifying coating thickness for ultra-slow release, or tailoring size for specific dispensers, the platform is adaptable. We see these pellets not as a final product, but as the foundation for collaborative innovation—where hygiene solutions evolve alongside customer challenges.

In a world where cleanliness defines credibility, sometimes the smallest components make the biggest difference. High-grade cotton bleach hanging pellets may be compact, but their impact resonates across industries, timelines, and standards. And when sourced directly from the source, they represent more than value—they represent vision.