Steam curls gently above a wide treatment tank in a textile mill at dawn. A worker tears open a vacuum-sealed bag, and a cascade of small, ivory-white pellets tumbles into the water. They sink slowly, releasing a steady stream of micro-bubbles as they dissolve. Within minutes, stained cotton fabric begins to brighten—impurities vanish without harsh agitation. No dust clouds, no measuring errors, no wasted chemicals. Just clean, consistent results.

What if one simple shift in form could redefine efficiency in industrial bleaching? Enter the revolution quietly unfolding in basins and processing lines across continents: the high-grade cotton bleach hanging pellet.

Form Meets Function: From Powder to Pellet — The Engineering Behind Efficiency

For decades, textile processors relied on powdered or liquid bleach agents—both effective but fraught with operational challenges. Powders create airborne particles that endanger respiratory health and contaminate workspaces. Liquids, while easier to dose, require precise mixing, refrigeration, and are prone to degradation over time. Both often lead to overdosing due to inconsistent application.

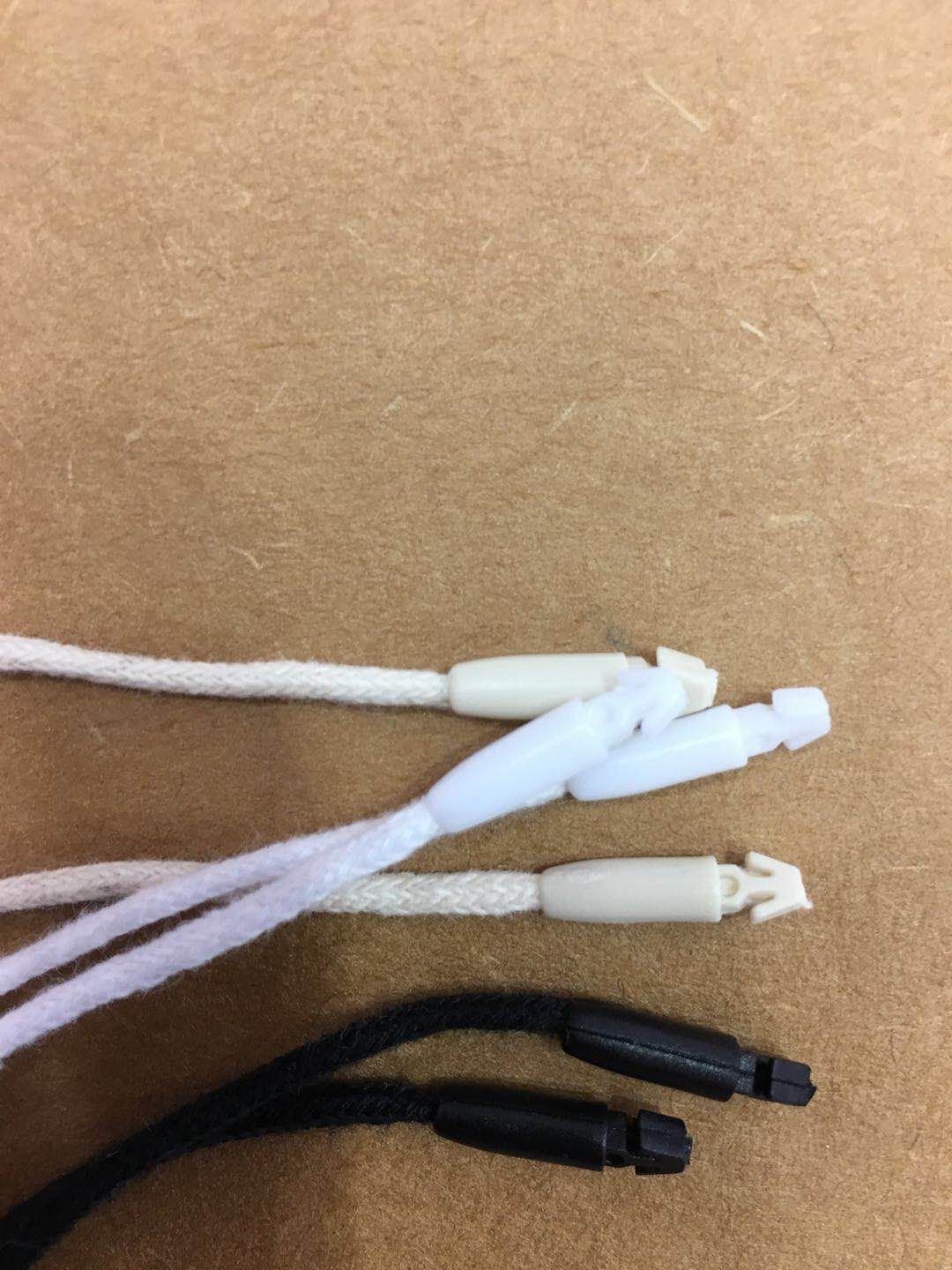

The bullet-shaped hanging pellet solves these issues through intelligent design. Its dense, compact structure allows it to submerge gradually, dissolving at a calibrated rate determined by water temperature and flow. This slow-release mechanism ensures active oxygen is delivered exactly where and when it’s needed—maximizing performance while minimizing chemical consumption.

Beyond chemistry, this shape integrates seamlessly with automated systems. Operators simply load the pellets into designated baskets or dispensers; once submerged, they require no further intervention. It’s a “set-and-forget” solution ideal for continuous production lines, reducing labor input and human error.

The Science of Whiteness: How Premium Cotton Bleach Pellets Are Made

These aren’t ordinary bleach tablets. Each pellet begins with rigorously selected raw materials—high-purity sodium percarbonate and stabilizing co-agents—sourced to meet stringent textile safety standards. The manufacturing process avoids high-heat exposure, using cold compression technology to preserve chemical integrity and prevent premature activation.

But true innovation lies beneath the surface. Embedded antioxidants not only enhance stain removal but also protect cellulose fibers from oxidative damage—a common side effect of aggressive bleaching. The result? Brighter fabrics without compromised strength or texture. Garments last longer, feel softer, and maintain their quality through repeated washes.

Every batch undergoes multi-stage quality control: dissolution speed tests, active oxygen yield measurements, pH stability checks, and residue analysis. Only pellets meeting exact specifications are released—ensuring every unit performs identically, batch after batch.

Green by Design: A Sustainable Step Forward in Textile Processing

In an era demanding greener practices, these pellets deliver more than just cleanliness—they support environmental responsibility. Their low-residue formula breaks down into water, oxygen, and soda ash—naturally occurring substances that pose minimal risk to aquatic ecosystems.

Because the controlled release prevents rapid depletion of active ingredients, facilities use up to 18% less bleach annually compared to traditional methods. One European eco-conscious apparel brand reported significant reductions in both chemical procurement costs and wastewater treatment loads after switching to hanging pellets—achieving dual wins in sustainability and profitability.

Compliant with Oeko-Tex® Standard 100 and other international eco-textile benchmarks, these pellets empower manufacturers to align with global ESG goals without sacrificing output quality.

Beyond Cotton: A Versatile Solution Across Industries

While optimized for cotton, these pellets excel in diverse applications. Home textile producers rely on them for deep whitening of bed linens and towels. Medical fabric suppliers use them in sterile wipe pre-treatment, ensuring hygiene without fiber degradation. Industrial laundries appreciate their reliability in heavy-duty cleaning cycles, including high-temperature boiling and continuous dyeing line prep.

In Southeast Asia, factory supervisors note fewer clogs in dosing systems and reduced maintenance downtime. In Italy, artisans restoring vintage textiles praise the gentle yet effective lift of aged stains without damaging delicate weaves. Whether used in large-scale automation or artisanal restoration, the hanging pellet adapts with precision.

Direct from Source: Why Cutting Out the Middleman Changes Everything

Traditionally, specialty chemicals pass through multiple distributors before reaching end users—each layer adding cost, delay, and potential variability in storage conditions. By selling directly from the manufacturer, we eliminate those inefficiencies.

This direct model means transparent pricing, fresher product batches, and faster delivery. More importantly, it opens the door to customization. Need a slower dissolution rate for cold-water operations? Want adjusted oxygen output for sensitive blends? We collaborate directly with clients to tailor formulations—something intermediaries rarely offer.

To lower adoption barriers, we provide small trial samples—letting you test performance on your own lines before scaling up. No long contracts, no inventory risks. Just real-world validation.

The Future of Clean: Small Pellets, Big Impact

As smart factories evolve, so too will the role of intelligent cleaning agents. Imagine bleach pellets equipped with RFID tags or paired with IoT sensors that monitor dissolution rates in real time, feeding data to central control systems for predictive dosing. The hanging pellet isn’t just a product—it’s a node in tomorrow’s connected textile ecosystem.

Sometimes, the most transformative innovations come not in flashy packages, but in humble forms. That small white pellet sinking silently into a tank may look unremarkable—but within it lies a convergence of material science, sustainable engineering, and supply chain transparency.

As the sun sets over a modern textile plant, rolls of flawlessly bleached cotton glide off the line like rivers of light. And somewhere upstream, a single pellet finishes its journey—having done its part, quietly, efficiently, perfectly.