Premium bleach pellets designed for maximum industrial performance — directly from production line to application site.

In an era where industrial efficiency and environmental responsibility must coexist, a new standard is emerging in chemical treatment processes. Meet the High-Grade Bullet Large 1 Cotton Bleach Hanging Pellet — a breakthrough innovation that fuses advanced design, raw material integrity, and intelligent delivery into one powerful solution. Manufactured at source and delivered without intermediaries, this product isn’t just another bleaching agent; it’s a redefinition of what industrial chemistry can achieve.

When Shape Meets Function: The Science Behind the Bullet Design

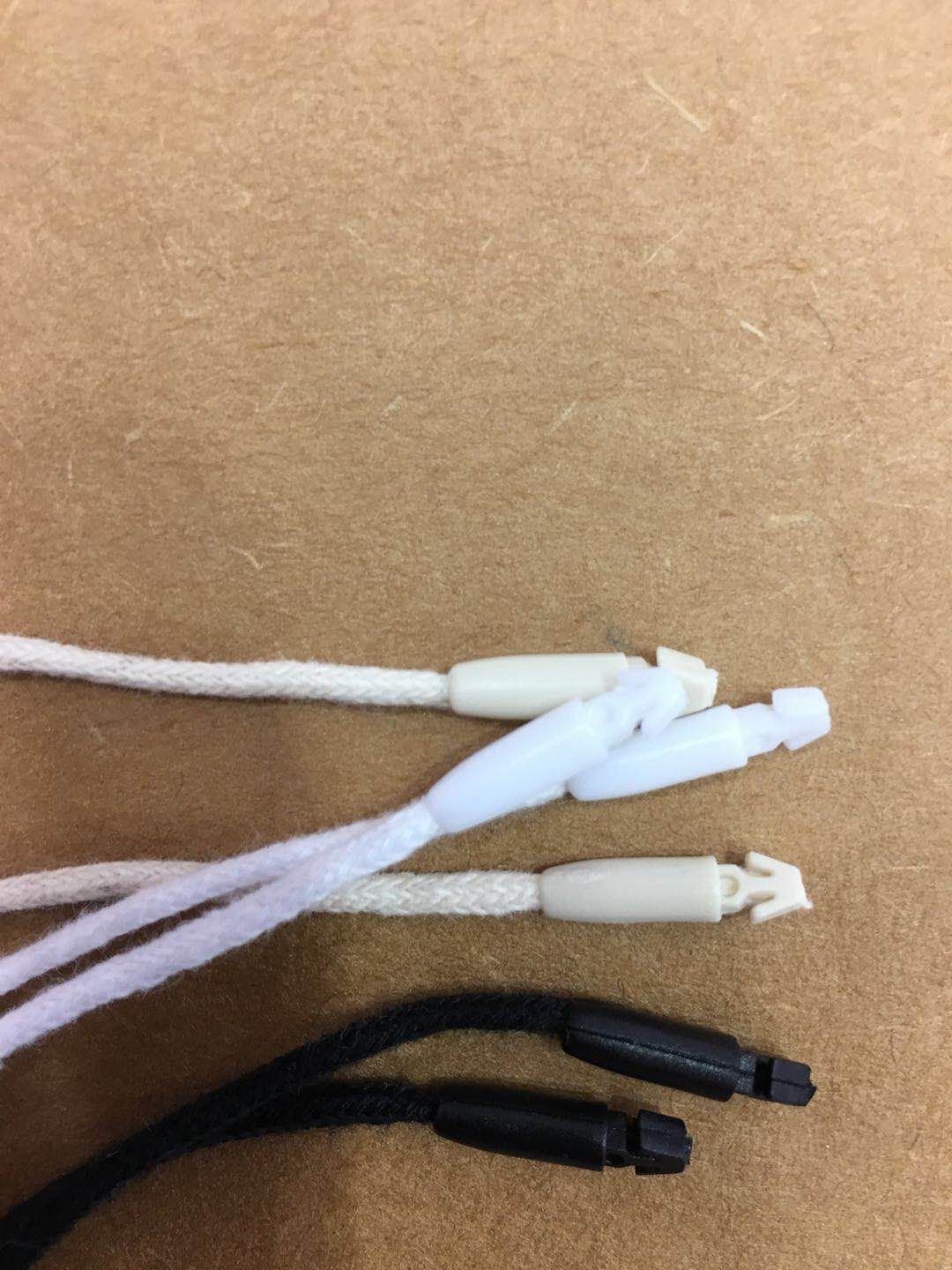

Precision-engineered geometry ensures controlled dissolution and deep penetration.

The distinctive bullet shape of the Large 1 pellet is not merely aesthetic—it's rooted in fluid dynamics and reaction kinetics. Unlike traditional granules or powders that disperse unevenly, the streamlined form allows for consistent movement through liquid systems, minimizing clumping and maximizing surface exposure over time. This controlled dissolution profile enables deeper penetration into fiber matrices in textile processing or more uniform oxidation in water treatment tanks. By optimizing the physical interaction between the active ingredient and its environment, the bullet design reduces processing time and enhances overall efficacy—proving that sometimes, the most impactful innovations begin with shape.

From Cotton Field to Pellet: The Journey of Purity

Sustainably sourced cotton fibers undergo rigorous purification before forming high-efficiency bleach carriers.

Every pellet begins with nature—specifically, premium-grade cotton fibers selected for their low lignin content and high cellulose stability. These fibers are processed through a proprietary purification cascade that removes impurities while preserving structural integrity. The cleaned biomass then acts as a natural scaffold for chlorine-based active agents, allowing for even distribution and stabilized release. Because we control the entire supply chain—from raw material sourcing to final compression molding—we ensure unmatched consistency across batches. This traceability from farm to factory floor translates into predictable performance, batch after batch.

The Smart Advantage of Hanging Application

Hanging deployment ensures gradual, targeted release with minimal waste.

Pouring loose bleach powder may be conventional, but it’s far from optimal. It often leads to rapid localized concentration spikes, inconsistent treatment, and increased operator exposure. Our hanging pellet system changes the game. Suspended directly in flow paths or holding tanks, the pellets dissolve gradually, maintaining a steady concentration of active ingredients over extended periods. This method drastically reduces chemical waste, lowers labor requirements, and improves safety by minimizing direct handling. In textile mills, this means whiter fabrics with less reprocessing. In municipal wastewater plants, it translates to reliable disinfection with fewer maintenance cycles.

Beyond Bleaching: Unlocking Multifunctional Industrial Potential

While originally engineered for textile whitening, these pellets have proven remarkably adaptable across sectors. Their stable formulation performs reliably under varying pH levels and temperatures, making them ideal for pulp and paper delignification, pre-treatment of industrial effluents, and even enhancement of cleaning formulations in food processing environments. Trials in alkaline boiler wash systems have shown significant reduction in organic scaling, thanks to the synergistic action of oxidant and cotton-derived dispersants. This versatility stems from a core principle: build a robust, responsive carrier system, and the applications will follow.

Direct from Manufacturer: Where Value Meets Velocity

By eliminating distributors and brokers, we deliver not only cost savings but also greater agility. Customers gain access to volume pricing typically reserved for large conglomerates, along with the ability to request custom modifications—such as adjusted dissolution rates or packaging formats—without navigating layers of resellers. More importantly, our technical support team operates within the same facility as R&D and production, enabling real-time troubleshooting and rapid feedback integration. When you buy direct, you're not just purchasing a product—you're entering a collaborative partnership focused on continuous improvement.

The Future of Bleaching: Can Performance Be Sustainable?

Sustainability isn't a side project—it's central to our roadmap. Current research focuses on developing a fully biodegradable outer coating that maintains structural integrity during use but breaks down safely post-dissolution. We’ve already reduced packaging waste by 40% through concentrated stacking designs and reusable shipping containers. Furthermore, our next-generation formula aims to lower residual chloride levels, reducing downstream ecological impact without sacrificing oxidative power. We believe high performance and planetary responsibility aren’t mutually exclusive—they’re interdependent.

The High-Grade Bullet Large 1 Cotton Bleach Hanging Pellet represents more than incremental progress. It embodies a holistic approach to industrial chemistry—one where engineering precision, supply chain transparency, and environmental stewardship converge. As industries worldwide seek smarter, cleaner, and more efficient solutions, this is the kind of innovation that doesn’t just meet demand—it anticipates it.