As the global textile industry continues to evolve, so too must the methods used to produce high-quality cotton fabrics. Traditional bleaching techniques, while once effective, are increasingly being outpaced by modern demands for speed, consistency, and sustainability. Enter bullet pellets — a game-changing innovation designed to revolutionize the cotton bleaching process for large-scale manufacturers.

Breaking the Limits of Traditional Bleaching Methods

For decades, textile producers have relied on conventional bleaching agents that require complex handling, long processing times, and frequent quality checks. These outdated methods often lead to inconsistent results, increased labor costs, and a higher risk of chemical mishandling. In an industry where efficiency and reliability are paramount, the need for a more advanced solution has never been greater.

Bullet pellets have emerged as a breakthrough alternative, offering a streamlined, safer, and more efficient way to achieve superior cotton bleaching. Their unique formulation allows for even distribution and controlled release, significantly improving process efficiency while reducing the risk of human error.

Why Going Direct to the Manufacturer Makes Sense

Many textile companies unknowingly pay a premium due to intermediaries in the supply chain. Middlemen can inflate prices, delay delivery, and obscure the traceability of product quality. By sourcing directly from the manufacturer, businesses can eliminate unnecessary overhead and ensure they receive the highest grade of bullet pellets at the most competitive cost.

A case in point is a major textile mill in Southeast Asia that transitioned to direct procurement. Within just six months, they reported a 20% reduction in operational costs, improved product consistency, and faster delivery cycles. This is the power of cutting out the middleman and working directly with the source.

Small Pellets, Big Impact: The Science Behind the Solution

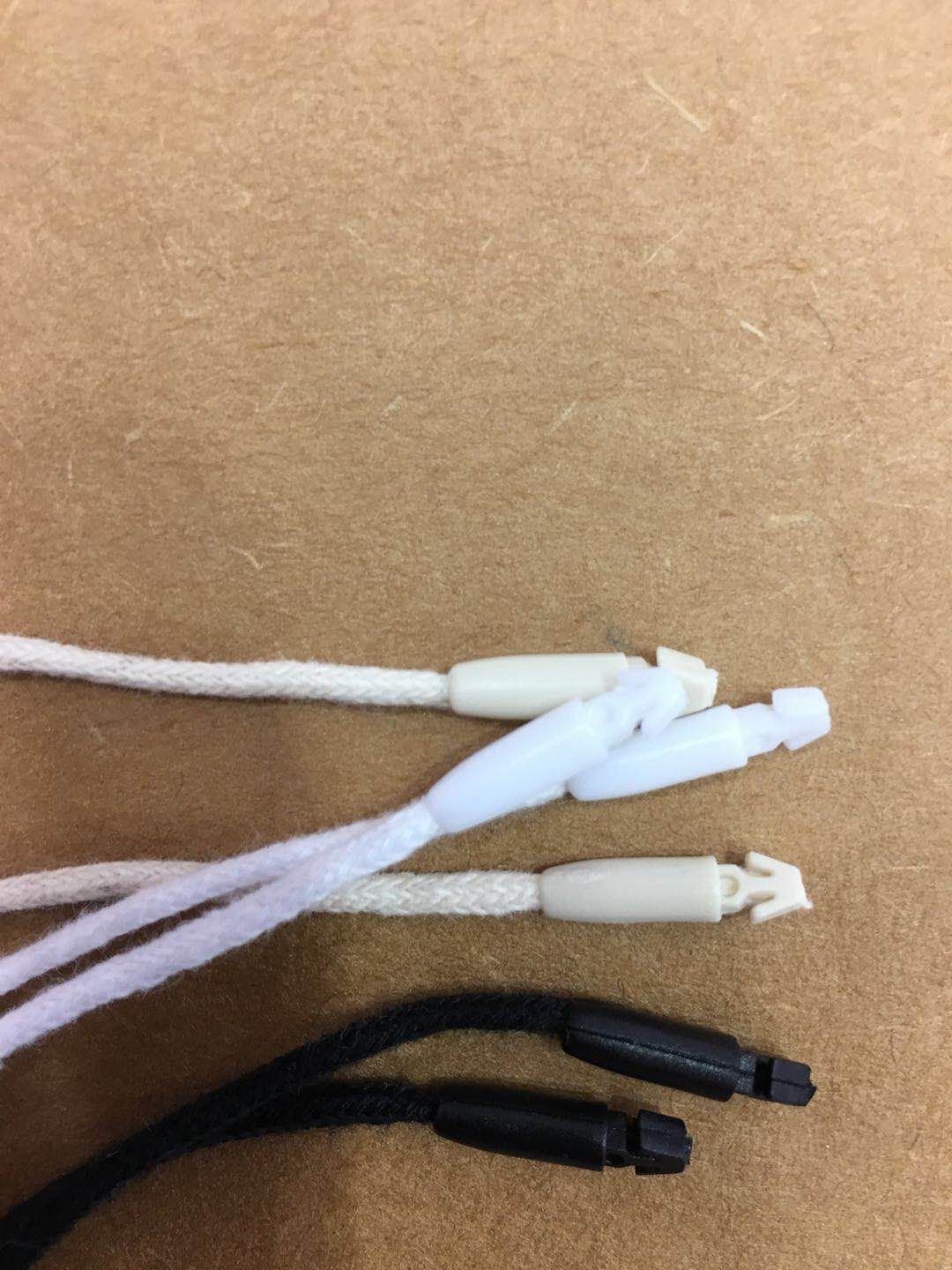

So, what exactly are bullet pellets? These are specially engineered granules designed to release active bleaching agents in a controlled and uniform manner. Unlike traditional powder or liquid bleach, bullet pellets dissolve gradually during the bleaching process, ensuring even coverage and optimal chemical reaction time.

Three key advantages set bullet pellets apart:

- Uniform Release: Ensures consistent bleaching results across large batches.

- Enhanced Safety: Reduced risk of chemical exposure and easier handling.

- Convenient Storage: Stable at room temperature, requiring no special storage conditions.

Lab tests have shown that bullet pellets can increase bleaching efficiency by up to 30% compared to traditional methods, with a noticeable improvement in fabric whiteness and softness.

Perfect for Industrial-Scale Applications

Whether you're running a high-volume cotton processing plant or a textile mill with strict quality standards, bullet pellets are designed to meet the needs of large-scale operations. They are particularly well-suited for industrial cotton bleaching, pre-treatment of fabrics, and facilities that must adhere to both environmental and efficiency benchmarks.

Smaller operations can also benefit from bullet pellet technology by adopting scaled-down dosing systems, while larger production lines can integrate automated dispensing units for maximum efficiency. Regardless of size, bullet pellets offer flexibility and performance that traditional bleaching agents simply cannot match.

Green Bleaching: Sustainability Meets Performance

In today's textile landscape, environmental responsibility is no longer optional — it's a necessity. Bullet pellets contribute to a cleaner production process by reducing chemical waste and minimizing the amount of water required for rinsing. Additionally, their controlled release mechanism lowers the risk of chemical runoff, helping factories meet stringent environmental regulations.

The manufacturer continues to invest in green chemistry and sustainable production practices, aiming to further reduce the environmental footprint of their products while maintaining top-tier performance. Future iterations of bullet pellets are expected to incorporate even more eco-friendly components without compromising on efficiency.

Real-World Feedback from Production Floors

Feedback from textile manufacturers across Asia, Africa, and Latin America has been overwhelmingly positive. Operators report reduced processing times, fewer manual adjustments, and a significant drop in chemical-related incidents.

One plant in India saw a 25% reduction in labor hours dedicated to bleaching after switching to bullet pellets. Another in Kenya noted improved fabric quality and higher customer satisfaction rates. As one operator put it, “It’s like switching from a manual typewriter to a modern word processor — everything just works better.”

Common Questions from New Users:

- Can bullet pellets be used with existing bleaching equipment?

- Do they require special storage conditions?

- Are they compatible with all types of cotton fabrics?

- How do they compare in cost per kilogram to traditional bleach?

- Is there any risk of fabric damage?

Rest assured, bullet pellets are designed for seamless integration, standard storage, broad compatibility, and cost efficiency — with no compromise on fabric integrity.

Looking Ahead: The Future of Cotton Bleaching

As the textile industry moves toward smarter, cleaner, and more modular production systems, bullet pellets are poised to evolve alongside these trends. Manufacturers are already exploring smart packaging that integrates with IoT-enabled monitoring systems and developing customizable pellet formulations tailored to specific fabric types and production requirements.

By embracing a collaborative approach with customers, the bullet pellet provider is committed to continuous innovation — from improving bleaching performance to offering tailored solutions that meet the unique needs of each textile producer. The future of cotton bleaching isn’t just efficient — it’s intelligent, sustainable, and adaptable.