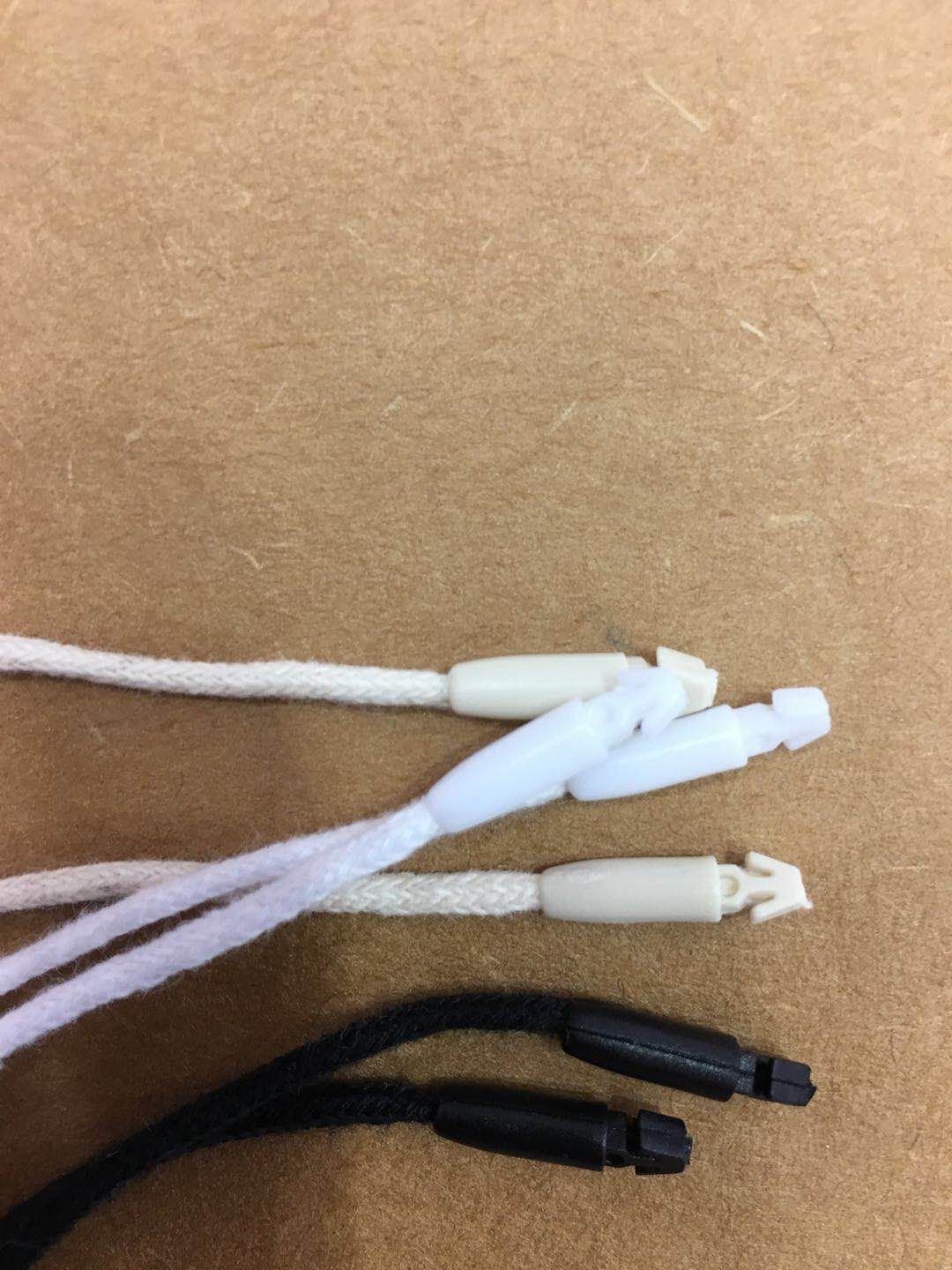

Premium cotton bleach hanging pellets designed for maximum absorption and consistent release.

In the world of industrial cleaning, textile processing, and chemical treatment, not all bleaching agents are created equal. Behind every successful process lies a critical component — the medium that delivers active ingredients efficiently and safely. Enter high-grade cotton bleach hanging pellets, a game-changer in controlled-release bleaching solutions. Crafted from natural, high-purity cotton and engineered with precision, these bullet-shaped pellets offer unmatched performance, especially when sourced directly from the manufacturer.

From Field to Finish: The Journey of a Cotton Pellet

The foundation of any superior product begins with its raw materials. Our bleach hanging pellets start with carefully selected long-fiber cotton, renowned for its strength, purity, and exceptional absorbency. Unlike synthetic carriers or low-grade fibers, premium cotton provides a clean, consistent matrix that holds and gradually releases bleach without introducing contaminants. This natural origin ensures compatibility across sensitive applications, particularly in textiles and food-safe environments where residue matters.

After harvesting and purification, the cotton undergoes a specialized compression and shaping process that maintains fiber integrity while enhancing structural stability. The result is a dense yet porous pellet capable of soaking up chlorine-based solutions and releasing them steadily over time — a vital feature for uniform bleaching results.

Why Shape Matters: The Science Behind the Bullet Design

The bullet shape optimizes water flow and dissolution rate for balanced chemical delivery.

You might wonder — why the bullet shape? It’s not just aesthetic. The elongated, tapered form of these pellets plays a crucial role in their functionality. When suspended in water or solution, the streamlined design allows for even saturation and predictable degradation. Unlike spherical or irregularly shaped pellets that may clump or dissolve unevenly, the bullet configuration promotes consistent exposure to liquid, minimizing channeling and maximizing contact surface area.

This geometric advantage translates into real-world benefits: more stable pH levels, reduced chemical waste, and longer-lasting effectiveness. Whether used in continuous-flow systems or batch treatments, this thoughtful design ensures reliability you can count on.

Behind the Scenes: What Makes Manufacturer-Direct Products Stand Out

When you buy high-grade cotton bleach hanging pellets directly from the manufacturer, you’re not just cutting out the middleman — you’re gaining access to superior quality control, transparent sourcing, and often, customizable options. Many distributors resell generic versions with inconsistent density or unknown origins. But by partnering straight with the source, customers benefit from rigorous batch testing, traceable production records, and responsive technical support.

Our facility adheres to strict manufacturing protocols, ensuring each pellet meets exact specifications for size, weight, and absorbency. With no markup layers, buyers also enjoy competitive pricing without sacrificing quality — an increasingly important factor in today’s cost-sensitive markets.

Performance Meets Practicality: Real-World Uses of Cotton Bleach Pellets

Widely used in textile mills, laundries, and sanitation units for reliable disinfection and whitening.

These versatile pellets have found homes far beyond traditional laundry rooms. In textile manufacturing, they enable gradual bleaching of fabrics without fiber damage. In commercial laundry operations, they reduce manual handling and improve dosing accuracy. Even wastewater treatment facilities utilize them for slow-release oxidation in containment tanks.

One customer in the hospitality sector reported a 30% reduction in chemical consumption after switching to our hanging pellets, thanks to minimized runoff and overflow. Another textile processor noted improved fabric brightness consistency across large dye lots — a testament to the pellet’s steady release profile.

Absorption Like Never Before: How High-Grade Cotton Boosts Efficiency

The magic lies in the material. Laboratory tests show that high-grade cotton fibers can absorb up to 25% more solution than standard cellulose blends, thanks to their open capillary structure. This means each pellet carries a higher payload of active ingredient, extending service life and reducing replacement frequency.

Moreover, because the cotton is naturally hydrophilic, it wicks moisture evenly throughout its core, preventing surface-only saturation. This deep absorption leads to prolonged, controlled release — essential for maintaining effective concentrations over hours or even days.

Choosing the Right Pellet: What to Look for in Cotton Bleach Products

Not all cotton bleach pellets deliver the same results. Key factors to consider include fiber origin, pellet density, dimensional consistency, and resistance to premature disintegration. Always ask for product specifications and, if possible, request samples before scaling up procurement.

Reputable manufacturers will provide data on absorption capacity (measured in mL/g), dissolution time, and compatibility with common bleach formulations. Packaging integrity and storage recommendations are also indicators of professionalism and attention to detail.

Eco or Not? The Environmental Impact of Cotton-Based Bleach Solutions

While no chemical process is entirely green, cotton-based pellets represent a step toward sustainability. Being biodegradable, they break down more readily than plastic-based alternatives, leaving less persistent waste. When paired with responsible disposal practices — such as neutralizing spent solutions before drainage — their environmental footprint shrinks further.

We encourage users to explore closed-loop systems where possible and recycle packaging materials. Some clients have even repurposed empty containers for internal logistics — a small win with cumulative impact.

The Future of Bleaching: Innovations in Cotton Pellet Technology

Next-generation designs focus on enhanced durability, smart release rates, and eco-conscious packaging.

Looking ahead, research is underway to enhance cotton pellets with time-release coatings and pH-responsive elements. Imagine a pellet that adjusts its output based on water temperature or contamination level — intelligent, adaptive, and efficient. As industries demand smarter, greener solutions, high-grade cotton remains at the forefront of innovation.

By investing in quality today, you're not just improving your current operations — you're preparing for the future of sustainable, precision-driven bleaching.