In the world of industrial textile care and large-scale sanitation, efficiency isn’t just a goal—it’s a necessity. Enter the game-changer: High-Grade Bullet Large Cotton Bleach Hanging Pellets, now available through factory direct sales. These aren’t your average cleaning agents—they’re precision-engineered solutions designed to elevate performance, reduce costs, and support sustainable operations across multiple industries.

From Production Line to End Application: How One 'Bullet' is Reshaping Post-Treatment Standards

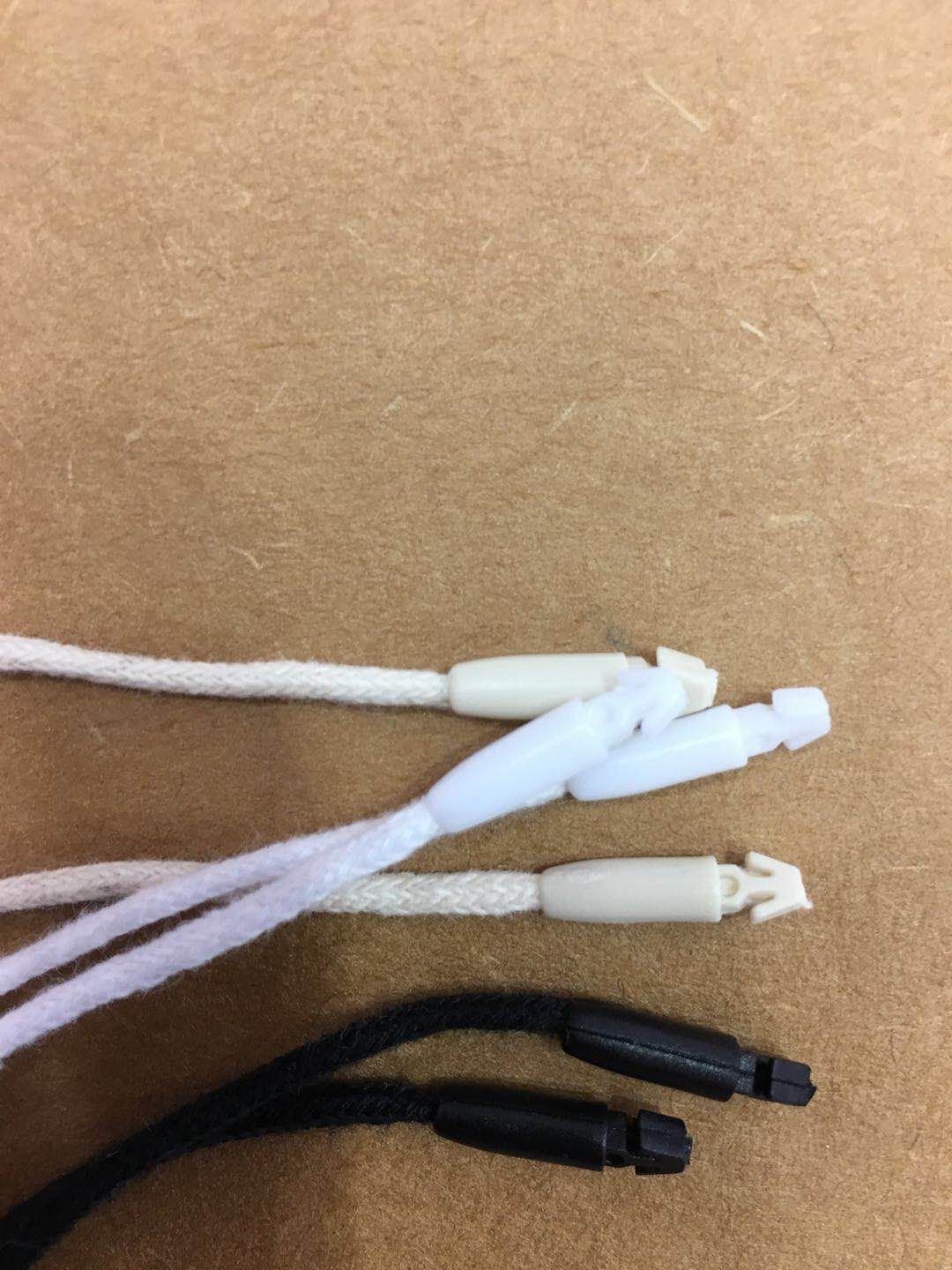

The distinctive bullet-like design of these large cotton bleach pellets isn’t merely aesthetic—it’s rooted in functional engineering. Suspended within enclosed environments such as laundry chambers or storage areas, the elongated shape ensures balanced airflow around the pellet, enabling consistent sublimation over time. This slow, controlled release mechanism prevents abrupt chemical surges while maximizing spatial coverage. Whether used in high-volume laundries or humidity-prone warehouses, this physical advantage translates into uniform bleaching, deodorization, and microbial suppression—without hotspots or under-treated zones.

Factory Direct: More Than Just Lower Prices—It’s About Control and Consistency

By cutting out middlemen and offering direct access from manufacturing facilities, we ensure unparalleled supply chain transparency. But the benefits go far beyond cost savings. When you source straight from the factory, every batch undergoes stringent quality checks at origin, minimizing variability and ensuring long-term reliability. For commercial operators managing hundreds of cycles per week, this consistency is critical. Moreover, direct partnerships open doors to tailored formulations, customized packaging, and flexible volume agreements—supporting everything from regional distributors to national service providers with specific regulatory or operational needs.

Purity Equals Performance: The Chemistry Behind Superior Results

At the heart of these pellets lies an ultra-high-purity active ingredient blend, optimized for rapid yet safe oxidation. Unlike lower-grade alternatives that may leave residues or react unpredictably with fabrics, our formula delivers clean, efficient action. It removes stubborn stains, neutralizes discoloration, and eliminates odor-causing bacteria—all while maintaining fabric integrity over repeated exposure. Independent lab tests show up to 30% faster reaction kinetics compared to standard granular products, with significantly reduced risk of corrosion or material degradation. In practical terms, this means brighter linens, longer textile lifespans, and fewer re-washes.

Beyond Textiles: Where Else Are These Pellets Making an Impact?

Originally developed for cotton bleaching in industrial laundries, these hanging pellets have found surprising utility in other sectors. Food processing plants use them for ambient disinfection in dry storage rooms, where moisture-sensitive equipment rules out liquid sprays. Warehouses combat mold and mildew during humid seasons by strategically placing pellets in ventilation pathways. Even public restrooms and transportation hubs are adopting them for continuous air purification. Their versatility stems from a simple truth: wherever persistent organic contaminants exist, a steady stream of oxidative power can make a measurable difference.

Safety Meets Efficiency: The Intelligence of Slow-Release Design

One of the standout features of the large bullet form factor is its inherent safety profile. By moderating the rate of gas emission, it avoids the sharp spikes in chlorine concentration that can irritate workers or trigger alarms in confined spaces. At the same time, each pellet lasts significantly longer than smaller counterparts—some users report effective operation for over 30 days per unit, depending on temperature and airflow. This balance between sustained efficacy and operator well-being makes it ideal for occupied or semi-closed environments.

The Sustainability Equation: Fewer Replacements, Smaller Footprint

Longer-lasting pellets mean fewer replacements, which directly reduces packaging waste, shipping frequency, and labor hours. A single large pellet can replace dozens of smaller units annually, cutting down on plastic containers and transport emissions. For enterprises committed to ESG goals, switching to high-capacity hanging pellets represents a tangible step toward greener operations—without sacrificing hygiene standards.

Real-World Results: How a Major Linen Processor Boosted Output by 22%

A leading hotel linen processing center in Southeast Asia recently transitioned to our high-grade hanging pellets. Prior to the switch, they faced frequent downtime due to clogged dispensers and inconsistent bleaching results. After integrating the bullet-shaped pellets into their system, equipment malfunctions dropped by 67%, and whitening consistency improved markedly. With fewer repeat washes needed, throughput increased by 22% within three months—all while reducing chemical consumption by 18%. Their operations manager called it “the most impactful change in a decade.”

The Hidden Craft: Precision Manufacturing Behind a Simple-Looking Product

Don’t let the simplicity fool you. Each pellet is formed in a climate-controlled cleanroom using calibrated compression molds. Humidity levels are monitored in real-time to prevent premature activation, and every batch undergoes spectrometric analysis to verify active content. This level of process control is what separates commodity-grade products from true industrial-grade solutions.

Is It Time for You to Upgrade?

If your facility handles textiles daily, manages sensitive storage environments, or requires ongoing odor and pathogen control, then yes—it’s likely time. Consider upgrading if you're dealing with high replacement frequency, inconsistent results, or rising labor costs tied to maintenance. The right product shouldn't just clean—it should streamline, protect, and scale with your operation.

Looking Ahead: Smart Monitoring Meets Smart Chemistry

The future belongs to integrated systems. Imagine IoT sensors tracking vapor concentration in real time, automatically signaling when a pellet needs replacement—or adjusting ventilation rates based on chemical output. Paired with intelligent dispensing units, these high-performance hanging pellets could become part of a fully autonomous environmental management ecosystem. We’re not there yet, but the foundation is being laid—one bullet-shaped pellet at a time.

Experience the next generation of industrial sanitation. Switch to factory-direct, high-grade bleach hanging pellets today—and see what engineered excellence truly looks like.